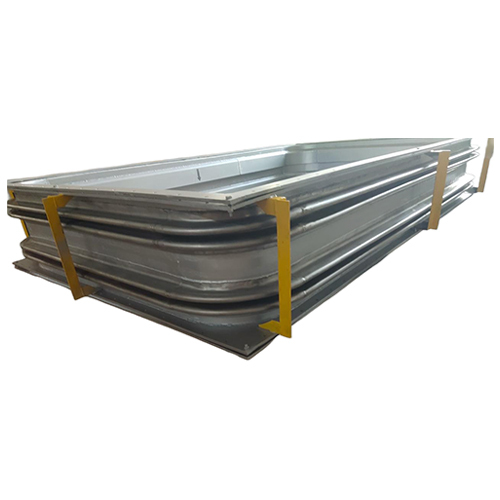

Single Tied Expansion Bellow

Price 5000.0 INR/ Unit

Single Tied Expansion Bellow Specification

- Surface Treatment

- Polished or Coated

- Max. Temperature

- Up to 700C (varies with material)

- Media

- Water, Gas, Steam, Oil, Chemicals

- Head Code

- Round

- Flange

- ANSI, DIN, BS, JIS Standard Flanges

- Material

- Stainless Steel, Carbon Steel, Inconel, Hastelloy, PTFE lined (as per requirement)

- Technique

- Formed and Welded

- Type

- Single Tied Expansion Bellow

- Connecting Type

- Flanged, Welded, or Threaded Ends

- Shape

- Cylindrical/Convoluted

- Working Pressure

- Up to 40 bar (depending on size and material)

- Corrosion Resistance

- Available with special materials or linings

- Manufacturing Length

- As customized per project

- Bellows Ply

- Single, Double, or Multi-ply Design

- Application Area

- Piping, Ducting, HVAC, Power Plants, Chemical & Petrochemical, Refineries

- Leak Test

- 100% Hydro-Tested

- Accessories

- Tie Rods, Liners, Covers

- Movement Absorbed

- Axial, Small Amounts of Lateral and Angular Movement

- End Connection

- Slip-on, Weld-neck, Threaded or as per client requirement

- Nominal Diameter Range

- 25 mm to 2000 mm

About Single Tied Expansion Bellow

Expansion bellows areflexible connectors used in piping, ducting, and machinery to absorb movement caused by thermal expansion, contraction, pressure changes, vibration, and misalignment. They act as a flexible joint, preventing stress and damage that could lead to system failure, leaks, or other damage. They are made from materials like metal (e.g., stainless steel) or rubber and are found in various industrial applications, including power plants, chemical industries, and medicalRobust Engineering for Demanding Applications

Single Tied Expansion Bellows are designed to efficiently absorb pipe expansion and contraction, especially in challenging environments such as power plants and chemical refineries. Their adaptability to various media, ranging from water to chemicals, along with a selection of advanced corrosion-resistant materials, ensures optimal long-term performance and safety under elevated temperatures and pressures.

Tailored Solutions and Reliable Quality

Each bellow is manufactured to meet specific project needs, with customizable lengths and ply designs. 100% hydro-testing ensures leak-proof operation. Customers can choose flange styles, connection types, and surface finishes as per installation requirements. Accessories like tie rods, liners, and covers provide added protection and functionality, making the product suitable for diverse industry sectors.

FAQ's of Single Tied Expansion Bellow:

Q: How is the axial movement absorbed by Single Tied Expansion Bellows?

A: Single Tied Expansion Bellows are engineered with a flexible convoluted structure that accommodates axial movement in the piping system. The tied configuration restrains excessive lateral and angular movement, while allowing the necessary axial expansion and contraction caused by temperature changes or pressure fluctuations.Q: What are the available size and material options for these bellows?

A: The bellows are available with nominal diameters ranging from 25 mm to 2000 mm and can be manufactured from stainless steel, carbon steel, Inconel, Hastelloy, or PTFE lining. Material selection depends on the application's temperature, pressure, and corrosion resistance requirements.Q: When should Single Tied Expansion Bellows be used in piping systems?

A: These bellows are recommended when controlled axial movement is required in piping, ducting, HVAC lines, or power and chemical plants. They are ideal for conditions involving thermal expansion, vibration, or system misalignment, where protection against leaks and corrosion is crucial.Q: Where can Single Tied Expansion Bellows be installed?

A: Single Tied Expansion Bellows are suitable for installation in industrial piping networks, HVAC ducts, chemical refineries, power plants, and petrochemical facilities. Their versatile flange and end connection options make them adaptable to various site requirements and standards.Q: What is the process for customizing a bellow to specific project requirements?

A: Customization begins with assessing the application's pressure, temperature, movement, and media specifications. Customers can select the nominal diameter, ply design, material, end connection type, surface treatment, and required accessories. Manufacturing length is tailored as per project needs, and each unit undergoes 100% hydro-testing to ensure leak-free integrity.Q: How does the corrosion resistance of the bellow benefit its application?

A: Corrosion resistance is achieved by selecting special alloys or applying protective linings, such as PTFE. This increases the product's longevity and reliability, especially in environments dealing with aggressive chemicals or high humidity, thereby reducing maintenance costs and downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Expansion Bellows

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Piece

Technique : Others

Material : Stainless Steel

Surface Treatment : Painted

Shape : Other

Fabricated Expansion Bellows

Price 35000.0 INR / Number

Minimum Order Quantity : 1 Number

Technique : Others

Material : Carbon Steel

Surface Treatment : Other

Shape : Other

Single Axial Expansion Bellows

Price 42000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Others, Seamless / Welded

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Surface Treatment : Other, Polished / Galvanized / Painted

Shape : Other, Cylindrical

Round Corner Expansion Bellows

Price 125000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Others, Welded

Material : Other, Stainless Steel / Mild Steel / Other Alloys

Surface Treatment : Other, Polished / Painted / Custom Coating

Shape : Other, Rectangular with Rounded Corners

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese