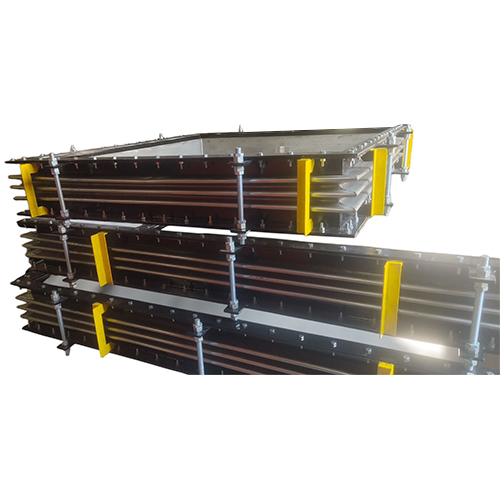

Expansion Bellows

Price 10000.0 INR/ Unit

Expansion Bellows Specification

- Head Code

- Round

- Flange

- Yes

- Media

- Air, SO2, Steam, Water, Acid, Gas

- Max. Temperature

- 100 Celsius (oC)

- Surface Treatment

- Painted

- Material

- Stainless Steel

- Usage

- Industrial Plants

- Technique

- Others

- Type

- Others

- Size

- 25NB to 5000NB

- Connecting Type

- Welding

- Height

- 300 Millimeter (mm)

- Product Type

- Expansion Bellows

- Shape

- Other

- Weight

- 40 Kilograms (kg)

- Color

- Silver

- Working Pressure

- 2 kgf/cm2

- Length

- 300 Millimeter (mm)

- Width

- 250 Millimeter (mm)

Expansion Bellows Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara, Gujarat

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- ISO 9001 : 2015

- Main Export Market(s)

- Middle East, Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe

- Main Domestic Market

- Bihar, Chandigarh, Daman and Diu, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Meghalaya, North India, All India, South India, Central India, West India, Gujarat, Karnataka, Kerala, Lakshadweep, East India, Mizoram, Manipur, Andhra Pradesh, Goa, Jharkhand, Odisha, Punjab, Assam, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttarakhand, West Bengal, Uttar Pradesh

About Expansion Bellows

An Expansion Bellows or Expansion Joint is a device used in piping systems to absorb thermal expansion contraction and other movements while maintaining a pressuretight seal

What Does an Expansion Bellows Contain

Bellows Element

The core component a corrugated flexible metal structure often stainless steel designed to absorb axial lateral and angular movements

Made from thinwalled metal sheets formed into convolutions for flexibility

End Connections

Flanges weld ends or threaded ends for connecting to the pipeline

These provide secure mounting and leakproof integration into the system

Inner Sleeve Liner optional

Protects the bellows from flowinduced vibration erosion and turbulence

Often used in highvelocity fluid or gas applications

Cover Shroud optional

External protective cover to shield the bellows from mechanical damage and environmental exposure

Tie Rods Control Rods optional

Absorb pressure thrust and prevent overextension

Common in restrained bellows to limit movement in specific directions

Hinges Gimbals optional

For special designs like hinged or gimbal expansion joints enabling controlled angular movements while resisting pressure thrust

Insulation if required

For hightemperature applications insulation materials may be wrapped around the bellows

Summary Table

Component Purpose

Bellows Element Flexibility for thermal and mechanical movement

End Connections Secure pipeline connection

Inner Sleeve Protects against erosion turbulence

Outer Cover Mechanical and environmental protection

Tie Rods Hinges Controls movement resists pressure thrust

Insulation optional Temperature management

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Fabricated Expansion Bellows

Price 35000.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Carbon Steel

Surface Treatment : Other

Technique : Others

Usage : ESP INLET

Single Axial Expansion Bellow

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Painted

Usage : Industrial Plants

Rectangular Expansion joint

Price 17000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Technique : Casting

Usage : Industrial

Universal Untied Expansion Bellows

Price 17500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polish

Technique : Casting

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese