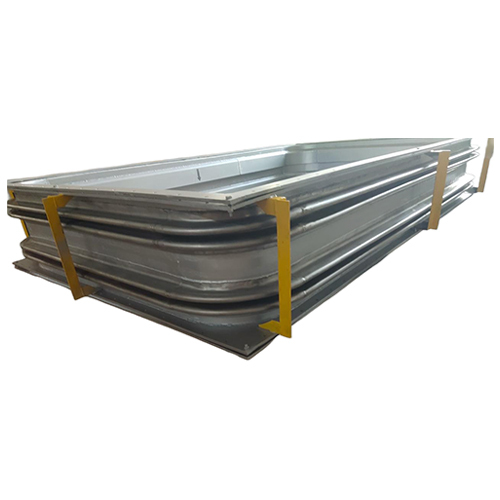

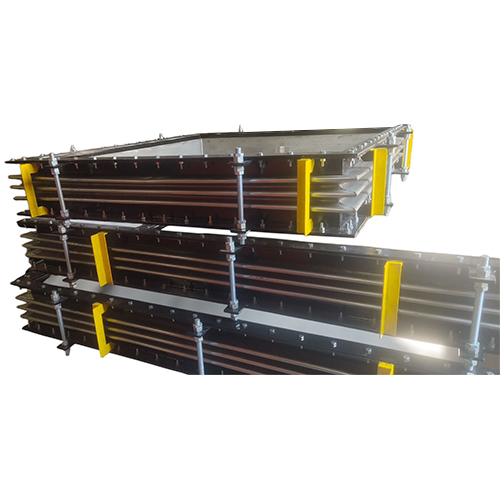

Round Corner Expansion Bellows

Price 125000.0 INR/ Unit

Round Corner Expansion Bellows Specification

- Max. Temperature

- Up to 450C (Depending on Material)

- Head Code

- Round Corner

- Media

- Gas, Liquid, Steam, Air

- Surface Treatment

- Polished / Painted / Custom Coating

- Flange

- Drilled to ANSI, DIN, or Custom Standards

- Material

- Technique

- Welded

- Type

- Round Corner Expansion Bellows

- Connecting Type

- Flanged / Welded Ends

- Shape

- Rectangular with Rounded Corners

- Working Pressure

- Up to 16 bar (or as per design)

- Corrosion Resistance

- High (Depends on Material Selection)

- Leak Tightness

- Helium Tested / Hydro Tested

- Standards

- Manufactured as per EJMA / ASME / BS / IS Standards

- End Connection

- Flanged, Butt Weld, or Custom

- Application

- HVAC, Pipeline Systems, Thermal Expansion Compensation

- Number of Ply

- Single or Multi-Ply as Required

- Size Range

- Customized as per requirement

- Liner

- Optional Internal Sleeve Available

- Movement Capability

- Axial, Lateral, and Angular Movements

About Round Corner Expansion Bellows

A round corner expansion joint is a type of metallic bellows designed to absorb multi-directional movement in large rectangular or square ducting systems, such as those for flue gas and air handling. Its design features rounded corners instead of sharp angles, which distributes stress more uniformly, prevents cracking, and extends the service life compared to mitered or camera corner joints. These joints are commonly used in high-temperature and high-pressure applications, like power plants and steel plants, and are fabricated from stainless steel or other alloys.Versatile Movement Capability

Engineered for maximum flexibility, these expansion bellows can accommodate axial, lateral, and angular movements. This feature makes them indispensable wherever pipelines or HVAC systems undergo thermal expansion or mechanical displacement, helping maintain safe and continuous operation.

Superior Leak Tightness and Robust Design

Every bellow is subjected to stringent helium or hydro testing to ensure complete leak tightness. With options for single or multi-ply construction, plus welded seams and corrosion-resistant materials, they offer reliable performance, even in challenging conditions.

Customizable Solutions for Diverse Applications

Manufactured to your exact dimensions, these bellows can be supplied with varying flange, end connection types, and internal sleeves depending on client requirements. Surface finishing and coating options further enhance their suitability for gas, liquid, steam, and air applications.

FAQ's of Round Corner Expansion Bellows:

Q: How do Round Corner Expansion Bellows accommodate different types of piping movement?

A: These bellows are specifically designed to absorb axial, lateral, and angular movements that occur due to thermal expansion or structural shifts in pipelines and HVAC systems, thus protecting your components from stress and potential damage.Q: What benefits do helium or hydro-tested bellows provide in terms of leak tightness?

A: Helium or hydro testing verifies the integrity of each bellow, ensuring leak tightness. This reduces the risk of media escape, which is crucial for maintaining system efficiency and safety, especially when handling gases, liquids, or steam.Q: When should I choose a single-ply or multi-ply bellows construction?

A: Single-ply bellows are suitable for standard applications with moderate movement. Multi-ply construction is recommended for higher movement, improved flexibility, or when greater durability is required, as it enhances overall strength and fatigue resistance.Q: Where are these expansion bellows commonly installed?

A: They are widely used in India across industries such as HVAC, industrial pipeline systems, and any installation that requires compensation for thermal expansion or misalignment in ducting or piping infrastructure.Q: What is the process for customizing size, material, or end connections?

A: You can specify dimensions, material choices, and preferred end connections (flanged, butt welded, or custom) while placing your order. Each bellow is then manufactured as per your technical requirements and relevant international standards.Q: Which materials provide optimal corrosion resistance for these bellows?

A: Corrosion resistance depends on material selection. Stainless steel is commonly chosen for its superior resistance, but other alloys can be used based on the media and environmental conditions present in your application.Q: How does the internal sleeve option improve usage in aggressive media or high-velocity flows?

A: Adding an internal sleeve protects the bellows from direct contact with abrasive or high-velocity media, reducing wear and extending the service life, especially in demanding gas, steam, or liquid flow applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Rectangular Expansion joint

Price 17000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Casting

Material : Stainless Steel

Surface Treatment : Powder Coated

Color : Silver

Single Axial Expansion Bellows

Price 42000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Others, Seamless / Welded

Material : Other, Stainless Steel / Carbon Steel / Alloy Steel

Surface Treatment : Other, Polished / Galvanized / Painted

Single Tied Expansion Bellow

Price 5000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Others, Formed and Welded

Material : Other, Stainless Steel, Carbon Steel, Inconel, Hastelloy, PTFE lined (as per requirement)

Surface Treatment : Other, Polished or Coated

Gimbal Expansion Joints

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Technique : Casting

Material : Iron

Surface Treatment : Powder Coated

Color : Silver

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese