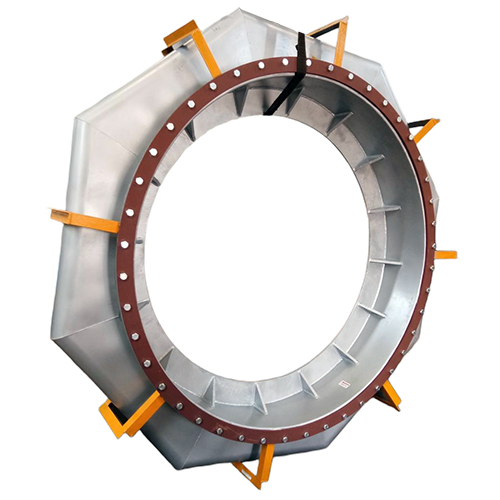

Octagonal Expansion Bellow

Price 215000.0 INR/ Unit

Octagonal Expansion Bellow Specification

- Max. Temperature

- 400C

- Flange

- ANSI/DIN Standard

- Head Code

- Octagonal

- Surface Treatment

- Polished

- Media

- Gas/Liquid

- Material

- Stainless Steel

- Technique

- Welded

- Type

- Expansion Bellow

- Connecting Type

- Flanged

- Shape

- Octagonal

- Working Pressure

- 10 Bar

- End Connections

- Welded/Flanged

- Leakproof

- Yes

- Movement Type

- Axial, Lateral, Angular

- Corrosion Resistance

- High

- Number of Convolutions

- Multiple

- Application

- Thermal Expansion Compensation

- Test Pressure

- Up to 15 Bar

- Size Range

- 50 mm to 1000 mm

About Octagonal Expansion Bellow

An octagonal expansion bellows is a flexible, eight-sided joint used in piping systems to absorb movement from thermal expansion, vibration, and misalignment, and in machine guarding to protect components from dust and damage. They are constructed from materials like stainless steel or rubber and can be found in heavy industrial applications like cement plants, chemical plants, and heavy machinery.Customizable Size and Superior Material

Octagonal Expansion Bellows are available in sizes from 50 mm to 1000 mm, constructed from polished stainless steel. This provides excellent resistance to corrosion, ensuring long-lasting durability even in demanding environmental conditions, whether you're dealing with gas or liquid media.

Reliable Performance for Thermal Expansion

Designed to compensate for thermal expansion in piping, these bellows efficiently absorb axial, lateral, and angular movements. Their leakproof structure and multiple convolutions ensure smooth operation and protection against system stress, enhancing overall reliability in industrial installations.

User-Friendly Installation and Maintenance

With the option of welded or flanged end connections-compatible with ANSI and DIN standards-these bellows offer straightforward integration into new or existing systems. Tested at pressures up to 15 Bar and a maximum temperature of 400C, maintenance requirements remain minimal, supporting uninterrupted operations.

FAQ's of Octagonal Expansion Bellow:

Q: How does the octagonal expansion bellow handle thermal expansion in piping systems?

A: The octagonal expansion bellow absorbs axial, lateral, and angular movements generated by thermal expansion, preventing stress and deformation in the piping network. Its multiple convolutions and robust construction ensure effective compensation for temperature fluctuations.Q: What benefits does high corrosion resistance provide for the expansion bellow?

A: High corrosion resistance, achieved through polished stainless steel, protects the bellow from chemical and environmental degradation. This extends its operational lifespan, reduces maintenance frequency, and maintains secure gas or liquid containment.Q: When should an octagonal expansion bellow be used in an industrial application?

A: It should be employed whenever thermal expansion or contraction is anticipated in pipework managing volatile or high-temperature media, particularly in industries requiring reliable leakproof performance and resistance to high pressures (up to 15 Bar) and temperatures (up to 400C).Q: Where are these expansion bellows commonly installed?

A: Octagonal expansion bellows are typically installed at points in piping systems that experience temperature variations, such as near boilers, heat exchangers, gas pipelines, or liquid transport lines, across factories, power plants, and processing facilities throughout India.Q: What is the process for installing the octagonal expansion bellow?

A: Installation involves securing the bellow to the piping using welded or flanged end connections compatible with ANSI/DIN standards. The leakproof design ensures that media remain contained, and proper alignment is crucial for maximizing movement absorption and system protection.Q: What types of end connections are available for these bellows?

A: The octagonal expansion bellows can be provided with either welded or flanged end connections, depending on the installation requirements. Flanged ends are available in ANSI or DIN standards for compatibility with a variety of piping systems.Q: What are the principal advantages of choosing this expansion bellow for gas or liquid media?

A: Key benefits include high corrosion resistance, excellent thermal expansion compensation, leakproof operation, and robust construction, supporting pressures up to 15 Bar and temperatures up to 400C. These features promote operational safety and longevity in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Single Axial Expansion Bellow

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Painted

Flange : Yes

Max. Temperature : 100 Celsius (oC)

Working Pressure : 3 kgf/cm2

Elbow Expansion Bellow

Price 15000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other

Flange : FLANGE END

Max. Temperature : 20 Degree C to +200 Degree C Celsius (oC)

Working Pressure : 0.3 N/mm2

Universal Expansion Joints

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Powder Coated

Flange : FLANGE END

Max. Temperature : 20 Degree C to +200 Degree C Celsius (oC)

Working Pressure : 0.1 MPA2.5MPA mpa

Octagonal Expansion Bellows

Price 55000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Galvanized / Polished

Flange : ANSI / DIN / IS Standard Flanges

Max. Temperature : Up to 700C

Working Pressure : Up to 25 Bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese