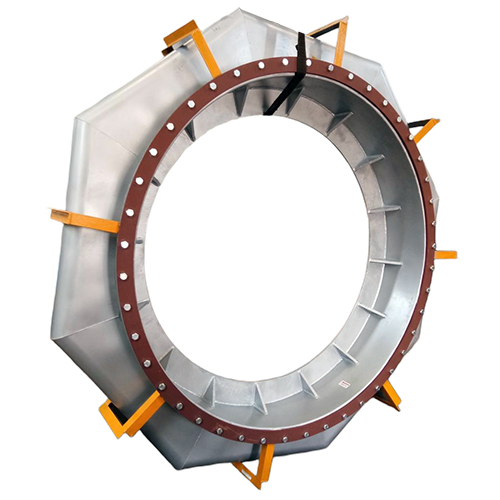

Octagonal Expansion Bellows

Price 55000.0 INR/ Unit

Octagonal Expansion Bellows Specification

- Surface Treatment

- Galvanized / Polished

- Head Code

- Octagonal

- Flange

- ANSI / DIN / IS Standard Flanges

- Max. Temperature

- Up to 700C

- Media

- Gas / Steam / Water / Chemical

- Material

- Stainless Steel / Carbon Steel / Alloy Steel

- Technique

- Welded / Formed

- Type

- Octagonal Expansion Bellows

- Connecting Type

- Flanged / Welded

- Shape

- Octagonal

- Working Pressure

- Up to 25 Bar

- Design Standard

- ASME, EJMA

- Corrosion Resistance

- Yes

- End Connection

- Flanged, Butt Weld, Socket Weld

- Length

- Custom as per requirement

- Axial Movement

- 10 mm to 80 mm

- Inspection

- 100% Radiography and Hydro Test

- Leak Test Pressure

- 1.5 × Working Pressure

- Diameter Range

- 50 mm to 2000 mm

- Application

- Pipelines, Boilers, HVAC, Refineries

About Octagonal Expansion Bellows

An octagonal expansion joint isa specialized industrial component designed to absorb movement, vibration, and stress in large, often non-circular, ducting and piping systems. They are used in high-temperature applications, such as in cement, steel, and power plants, to compensate for thermal expansion and contraction while also helping with minor misalignment and vibration isolation. The octagonal shape helps distribute stress more evenly than a rectangular joint and can reduce turbulence in high-pressure systems.Versatile Performance in Industrial Applications

With octagonal shape and robust construction, these expansion bellows are tailored for demanding environments such as pipelines, boilers, HVAC systems, and refineries. The product supports a wide variety of media, including gas, steam, water, and chemicals, and is compatible with flanges adhering to ANSI, DIN, and IS standards. Their corrosion-resistant materials and customizable lengths enhance longevity and adaptability.

Engineered for Safety and Reliability

Each bellow is manufactured to stringent ASME and EJMA standards, featuring a thorough inspection regime. This includes 100% radiography and hydrostatic leak testing at 1.5 times the working pressure, ensuring maximum safety and resilience under operational stress. The welded or formed technique assures a strong and durable construction for critical industrial processes.

FAQ's of Octagonal Expansion Bellows:

Q: How are Octagonal Expansion Bellows used in industrial piping systems?

A: Octagonal Expansion Bellows are installed in pipelines to absorb axial movement, reduce vibration, and compensate for thermal expansion. Their flexible design helps protect piping systems in applications such as boilers, HVAC setups, and refineries by relieving stress and preventing leaks or structural damage.Q: What is the standard process for installing these bellows?

A: Installation typically involves welding or bolting the bellows to the connecting pipes using flanged, butt weld, or socket weld end connections. The mounting process should follow the design standards (ASME/EJMA) and consider the specified movement and pressure ratings for secure and durable integration.Q: When should expansion bellows be selected for a project?

A: Expansion bellows should be chosen whenever a piping system is subject to thermal growth, movement, or vibration that could damage rigid pipe sections. They are especially recommended for high-temperature or high-pressure environments and where space or alignment issues occur.Q: Where are these bellows most commonly applied?

A: These bellows are widely utilized in industries such as oil and gas refineries, chemical processing plants, power stations, HVAC systems, and large-scale water or steam pipelines, offering reliable movement compensation and enhanced safety.Q: What are the main benefits of choosing octagonal-shaped bellows?

A: Octagonal bellows provide improved flexibility and strength over traditional shapes, offering superior stress distribution. Their geometric structure enables better handling of multiple movement directions while maintaining high corrosion resistance and pressure endurance.Q: How is quality ensured for these expansion bellows?

A: Quality is maintained through strict adherence to ASME and EJMA guidelines, with each unit subjected to 100% radiography and hydrostatic testing at 1.5 times the working pressure. This process ensures that all bellows are defect-free and ready for demanding service conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Capsule Expansion Bellow

Price 7000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Size : Custom

Universal Untied Expansion Bellows

Price 17500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polish

Technique : Casting

Size : Standard Sizes

Single Tied Expansion Bellow

Price 5000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel, Carbon Steel, Inconel, Hastelloy, PTFE lined (as per requirement)

Surface Treatment : Other, Polished or Coated

Technique : Others, Formed and Welded

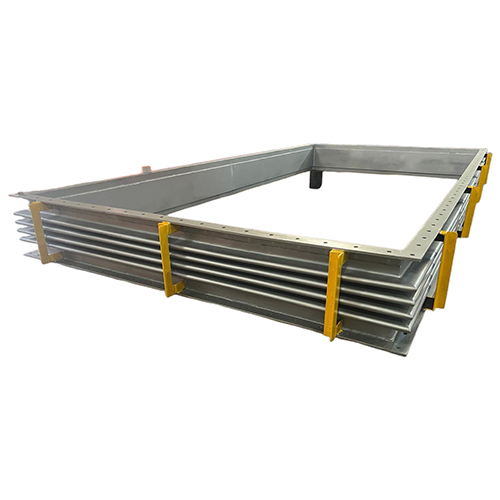

Rectangle Type Expansion Bellow

Price 60000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel / Mild Steel

Surface Treatment : Other, Polished / Painted

Technique : Others, Welding or Formed

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese