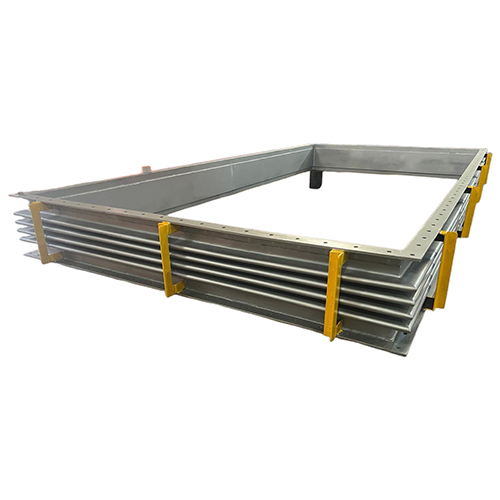

Rectangle Type Expansion Bellow

Price 60000.0 INR/ Unit

Rectangle Type Expansion Bellow Specification

- Flange

- Drilled to Standard

- Head Code

- Square / Rectangular

- Surface Treatment

- Polished / Painted

- Media

- Air, Fluids, Gas

- Max. Temperature

- Up to 400C

- Material

- Stainless Steel / Mild Steel

- Technique

- Welding or Formed

- Type

- Expansion Bellow

- Connecting Type

- Flange / Welded

- Shape

- Rectangular

- Working Pressure

- Up to 10 Bar

- Bellow Thickness

- 1 mm 3 mm

- Corrosion Resistance

- High

- Standards

- BS, ASTM, IS, DIN

- Compensating Length

- Customized

- Leakage Test

- 100% Factory Tested

- Internal Sleeve

- Optional

- Movement Type

- Axial, Lateral, Angular

- Expansion Range

- Custom-engineered

- Application

- HVAC, Exhaust Systems, Pipelines

- Dimensions

- As per customer requirement

About Rectangle Type Expansion Bellow

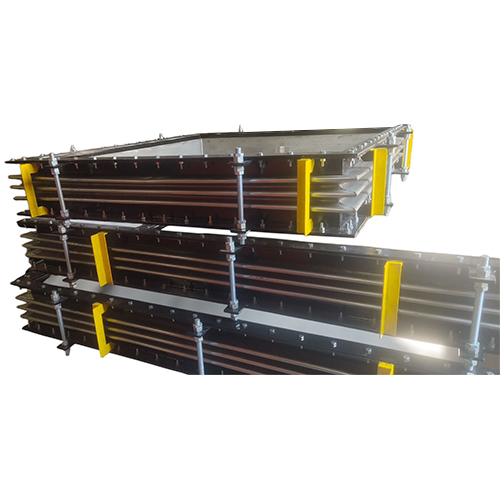

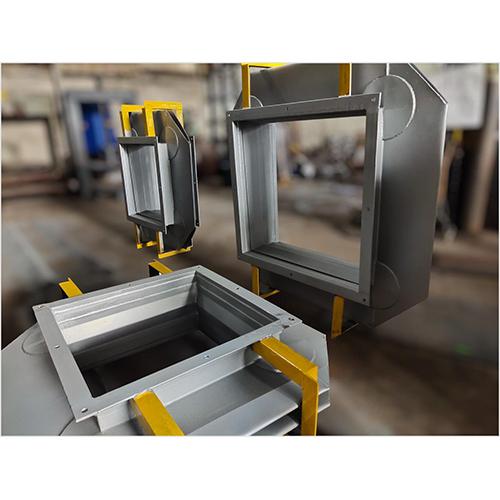

A metallic rectangular bellow is a corrugated expansion joint designed to absorb movement in systems with rectangular ducting, such as exhaust or HVAC systems. It is made of high-strength metals like stainless steel or alloys, offering durability, high temperature resistance, and corrosion resistance. These bellows are used to compensate for thermal expansion, vibration, and misalignment in industrial applications.Engineered for Demanding Environments

Designed to address movement in pipelines and ductwork, our rectangular expansion bellows effectively compensate for axial, lateral, and angular displacements. Their high corrosion resistance and rugged construction make them suitable for harsh environments, including HVAC, exhaust, and industrial fluid systems.

Customizable Design Options

Each expansion bellow can be tailored by thickness, compensating length, expansion range, and connection type to precisely fit your project requirements. Surface treatments such as polishing or painting further enhance durability and appearance, while internal sleeves are available upon request for specific applications.

Tested for Safety and Performance

Every bellow undergoes rigorous leakage testing at the factory, ensuring consistent quality and operational safety. Our products adhere to international standards (BS, ASTM, IS, DIN), affirming their reliability and suitability for global industrial use.

FAQ's of Rectangle Type Expansion Bellow:

Q: How do I determine the correct expansion bellow size and configuration for my system?

A: To select the appropriate expansion bellow, consider the required movement type (axial, lateral, angular), operating temperature (up to 400C), pressure (up to 10 Bar), media type (air, fluids, gas), and installation dimensions. Share these parameters with the manufacturer or supplier, who can provide custom engineering to fit your needs.Q: What materials and surface treatments are available for rectangle type expansion bellows?

A: Our bellows are manufactured using either high-quality stainless steel or mild steel. Surface finishing options include polished or painted treatments, enhancing both corrosion resistance and visual appeal based on your operational environment and aesthetic preferences.Q: When should an optional internal sleeve be considered for an expansion bellow?

A: An internal sleeve is recommended when the media flow involves high velocity, abrasive particles, or fluctuating temperatures. It protects the bellows from direct exposure, enhancing operational lifespan and reducing maintenance frequency.Q: Where are these expansion bellows applicable within industrial systems?

A: Rectangular expansion bellows are widely used in HVAC lines, exhaust systems, and process pipelines where thermal expansion, vibration absorption, or misalignment compensation is needed. Their versatility makes them suitable for a range of industrial, commercial, and utility sectors.Q: What is the manufacturing process for these bellows?

A: Bellows are produced through a precise welding or forming technique, depending on material and application requirements. All units are custom engineered, then thoroughly tested for leaks and performance compliance with international standards.Q: How does using a rectangular expansion bellow benefit my system?

A: These bellows reduce thermal stress and absorb movement or vibration, minimizing potential damage to pipes, ducts, or connected equipment. This results in enhanced durability, lower maintenance costs, and reliable system operation over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Rectangular Expansion joint

Price 17000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Usage : Industrial

Product Type : Expansion Joints

Size : Standard Sizes

Camera Corner Expansion Bellows

Price 15000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Usage : Industrial

Product Type : Expansion Bellow

Size : 1200 x 1200

Capsule Expansion Bellow

Price 7000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Usage : Industrial

Product Type : Capsule Expansion Bellow

Size : Custom

Universal Expansion Joints

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Iron

Usage : Industrial

Product Type : Universal Expansion Joints

Size : Standard Sizes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese