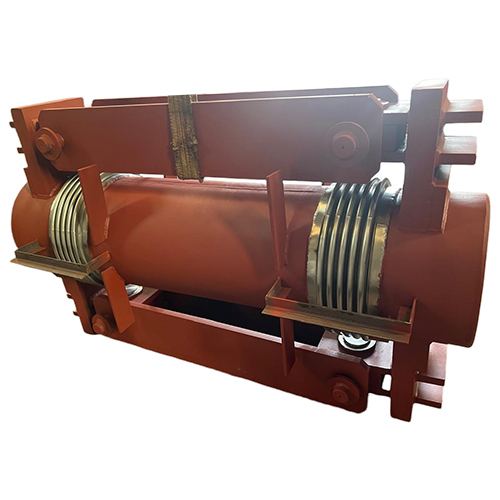

Hinge Type Expansion Bellow

Price 57000.0 INR/ Unit

Hinge Type Expansion Bellow Specification

- Surface Treatment

- Polished, Painted, Anti-corrosive

- Max. Temperature

- up to 600C

- Head Code

- Round

- Flange

- ANSI, DIN, BS Standard Flanges

- Media

- Air, Gas, Steam, Water

- Material

- Stainless Steel, Carbon Steel, Alloy Steel

- Technique

- Seamless, Welded

- Type

- Hinge Type Expansion Bellow

- Connecting Type

- Flanged, Welded

- Shape

- Cylindrical

- Working Pressure

- up to 40 bar

- Coating

- Epoxy or Customized

- Pressure Test

- Hydrostatic/Pneumatic

- Bellow Diameter

- 50 mm to 1500 mm

- Movement Capability

- Axial, Lateral, Angular

- Length

- Customized as per requirement

- Application

- Absorbs lateral and angular movements in piping systems

- Design Standard

- EJMA, ASME

- Number of Ply

- Single or Multi-ply

- Leakage Class

- Class V or as specified

- Spring Rate

- Customized per movement

- End Connection

- Flange, Butt Weld

About Hinge Type Expansion Bellow

A HINGE expansion bellows is a specialized component designed to absorb angular movement in a single plane within a piping system, while restricting other types of movement. It consists of a flexible bellows element and two hinges connected by a common pin, which allows it to bend in only one direction. These bellows are often used in pairs or sets of three and can handle external loads like piping weight, which reduces the need for additional anchors.Versatile Movement Absorption

Hinge Type Expansion Bellows offer exceptional flexibility by absorbing lateral, axial, and angular movements, ensuring reliable performance even in dynamic piping systems. Their hinge mechanism precisely restricts axial displacement while permitting safe lateral and angular deflection, minimizing stress and enhancing pipe longevity.

Customizable Design & Durable Materials

Tailored to meet specific application needs, these expansion bellows are available in diameters from 50 mm to 1500 mm, single or multi-ply construction, and various surface treatments. Manufactured from high-grade stainless, carbon, or alloy steel, the bellows withstand high temperatures and corrosive environments, contributing to robust, long-term system integrity.

Comprehensive Testing & Compliance

Each bellow is rigorously tested via hydrostatic and pneumatic methods to ensure leakage prevention. The products strictly adhere to EJMA and ASME international design standards, with flanged or welded connections compatible with ANSI, DIN, or BS standards, delivering peace of mind in safety and regulatory compliance.

FAQ's of Hinge Type Expansion Bellow:

Q: How does a hinge type expansion bellow function within piping systems?

A: The hinge type expansion bellow utilizes articulated hinge components that permit lateral and angular movement while restricting axial displacement. This design reduces mechanical stress on pipework, accommodating thermal expansion and misalignment, making it ideal for complex industrial piping networks.Q: What applications are suitable for hinge type expansion bellows?

A: These bellows are best suited for absorbing lateral and angular movements in piping systems carrying air, gas, steam, or water. They are commonly employed in power plants, refineries, and chemical industries, handling high temperatures and pressures up to 600C and 40 bar.Q: When should I select single-ply versus multi-ply construction for bellows?

A: Single-ply bellows are ideal for applications with moderate movement and pressure, while multi-ply designs offer increased flexibility and fatigue resistance, suitable for higher pressures or where frequent movement occurs. Selection depends on your specific system requirements and operating conditions.Q: Where can hinge type expansion bellows be installed?

A: These bellows can be installed in any section of piping systems requiring movement absorption, particularly in places with constrained geometry or exposed to thermal stresses. Their cylindrical, round head code shape enables easy integration with flanged or welded connections.Q: What is the process for customizing a hinge type expansion bellow?

A: Customization involves specifying parameters such as diameter (50 mm to 1500 mm), length, number of plies, material, end connection type, surface treatment, and required movement capabilities. Manufacturers design and produce bellows to match these criteria, ensuring optimal performance for your application.Q: How do the bellows benefit piping system longevity?

A: By absorbing movement and reducing stress concentrations, hinge type expansion bellows minimize the risk of pipe fatigue, cracks, and joint failure. Their anti-corrosive coatings and robust materials further enhance durability, decreasing the need for frequent system maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Single Axial Expansion Bellow

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Painted

Material : Stainless Steel

Working Pressure : 3 kgf/cm2

Usage : Industrial Plants

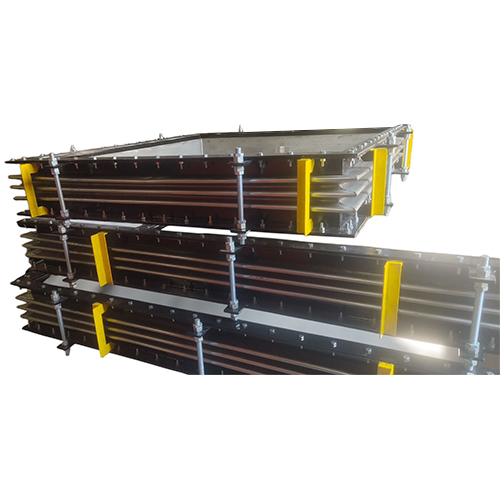

Rectangular Expansion joint

Price 17000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Powder Coated

Material : Stainless Steel

Working Pressure : 0.1 MPA2.5MPA mpa

Usage : Industrial

Expansion Bellow

Price 3000.0 INR / Number

Minimum Order Quantity : 1 Number

Surface Treatment : Polish

Material : Stainless Steel

Working Pressure : 0.1 MPA2.5MPA mpa

Usage : Industrial

Universal Expansion Joints

Price 50000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Powder Coated

Material : Iron

Working Pressure : 0.1 MPA2.5MPA mpa

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese