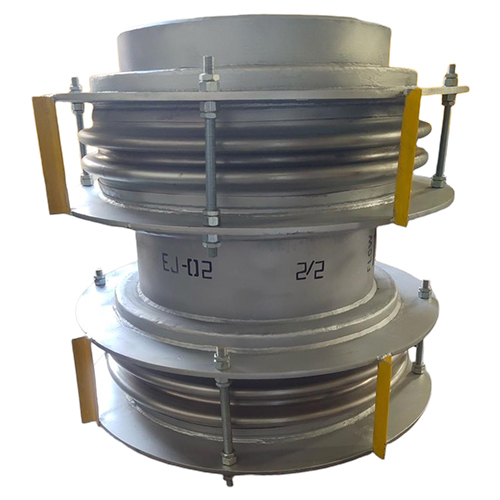

Metallic Expansion Joints

Price 20000.0 INR/ Unit

Metallic Expansion Joints Specification

- Max. Temperature

- 500 Celsius (oC)

- Head Code

- Round

- Media

- Air, Steam, Water, Oil, Gas, Acid

- Surface Treatment

- Painted

- Material

- Stainless Steel

- Usage

- Industrial Plants

- Technique

- Others

- Type

- Others

- Size

- 25NB to 5000NB

- Connecting Type

- Others

- Height

- As per requirement Millimeter (mm)

- Shape

- Other

- Product Type

- Metallic Expansion joint

- Weight

- 125 Kilograms (kg)

- Color

- silver

- Length

- Millimeter (mm)

- Working Pressure

- 1 kgf/cm2

Metallic Expansion Joints Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara, Gujarat

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Truck Load

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- ISO 9001 : 2015

About Metallic Expansion Joints

Metallic Expansion Joints are flexible connectors designed to absorb thermal expansion contraction vibration and misalignment in piping systems or ductwork They use metal bellows as the primary flexible element and are widely used in highpressure and hightemperature applications like power plants refineries chemical plants and HVAC systems

What Are Metallic Expansion Joints Made Of

A typical metallic expansion joint contains

Metallic Bellows Element

Made of stainless steel or other alloys eg Inconel Monel Hastelloy for corrosion and temperature resistance

Corrugated design provides flexibility for axial lateral and angular movements

End Connections

Weld Ends or Flanges for integration into the pipeline or equipment

Optional Internal Components

Inner Sleeve Flow Liner Protects bellows from erosion turbulence and highvelocity media

Outer Cover Shroud Provides mechanical protection and shields against environmental damage

Optional Restraints Hardware

Tie Rods Control pressure thrust and limit movement

Hinges or Gimbals Enable angular movements while absorbing pressure thrust

Limit Rods Prevent overextension or compression

Functions of Metallic Expansion Joints

Absorb thermal expansion and contraction of piping

Isolate vibration and noise from rotating machinery

Compensate for minor misalignment

Reduce load on anchors and equipment

Types of Metallic Expansion Joints

Single Axial Expansion Joint Absorbs axial movement only

Universal Expansion Joint Two bellows connected by a spool for large lateral movement

Hinged Expansion Joint Absorbs angular rotation in a single plane

Gimbal Expansion Joint Handles angular rotation in multiple planes

Pressure Balanced Expansion Joint Compensates for axiallateral movement while neutralizing pressure thrust

Advantages

High strength and durability under pressure and temperature extremes

Suitable for steam gas oil and chemical pipelines

Longer service life compared to rubber or fabric joints

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Square Type Camera Corner Expansion Bellows

Price 12000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Product Type : Square Type Camera Corner Expansion Bellows

SS Expansion Bellow

Price 10000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polish

Product Type : SS Expansion Bellow

Shape : Other

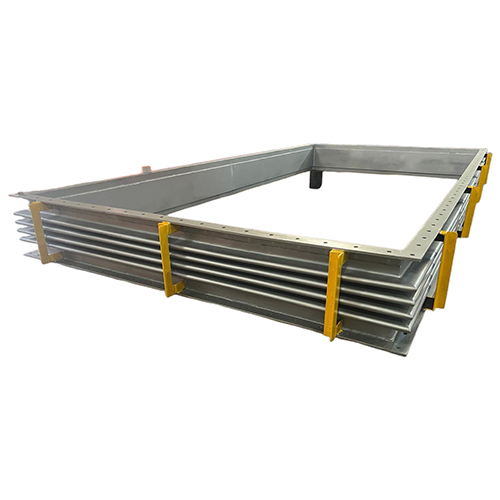

Rectangle Type Expansion Bellow

Price 60000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Stainless Steel / Mild Steel

Surface Treatment : Other, Polished / Painted

Shape : Other, Rectangular

Circular Universal Expansion Bellow

Price 15000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Iron

Surface Treatment : Powder Coated

Product Type : Universal Expansion Joint

Shape : Equal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese