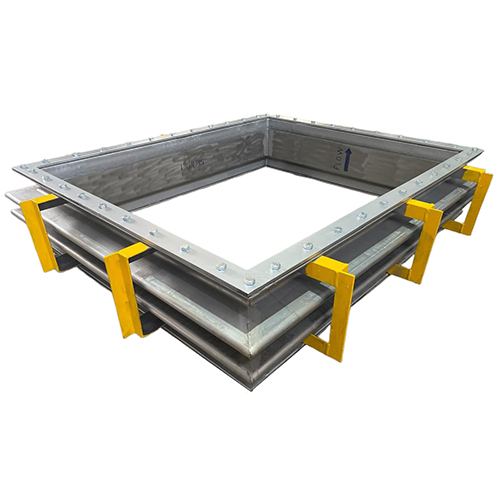

Double miter Rectangle Expansion Bellow

Price 44000.0 INR/ Unit

Double miter Rectangle Expansion Bellow Specification

- Max. Temperature

- Up to 600C (Depending on Material)

- Media

- Surface Treatment

- Polished / Galvanized as required

- Flange

- Custom Drilled Flanges as per Standard or Customer Drawing

- Head Code

- Rectangle

- Material

- Stainless Steel / Mild Steel / Alloy Steel (customized on demand)

- Technique

- Welded and Formed by Pressing & Miter Construction

- Type

- Double Miter Expansion Bellow

- Connecting Type

- Flanged / Welded End

- Shape

- Rectangular

- Working Pressure

- 0.5 to 10 Bar (customizable)

- Application

- Ducting, Air Handling, Exhaust System, Industrial Applications

- Corrosion Resistance

- High, depending on material

- Leakage Test

- Hydrostatic / Pneumatic as per standard

- Size Range

- Custom-manufactured as per site requirement

- Movement Capability

- Axial, Lateral, and Angular

- Design Standard

- ASME / EJMA / IS: specified by client

- Bellows Ply

- Single Ply or Multi Ply (as per design)

- End Connection

- Flanged / Butt Weld / Custom

- Color

- Metallic Silver / Customized Paint Finish

About Double miter Rectangle Expansion Bellow

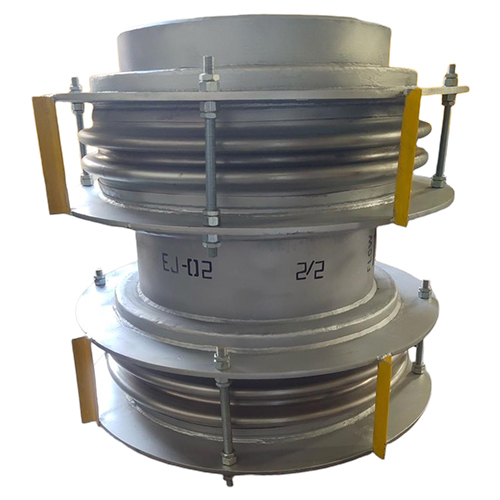

A square double miter expansion joint is a specific type of rectangular metallic expansion joint used in ducting and piping systems to absorb thermal expansion and vibration. It is designed with two mitered corners (a 45-degree angle cut on each of two pieces to form a 90-degree corner).Engineered for Versatility and Performance

Designed for optimal movement-axial, lateral, and angular-the Double Miter Rectangle Expansion Bellow adapts seamlessly to thermal shifts and mechanical stresses in industrial piping systems. Its robust construction and custom-sized profiles ensure suitability for any installation, while a polished or galvanized exterior boosts durability in demanding atmospheres.

Tailored to Your Project Needs

Every bellow is custom-manufactured to site-specific dimensions and performance requirements, with a selection of materials, ply thickness, and surface treatments. End connections and flange designs are configured as per client drawings or industry standards, creating a seamless fit into new or retrofit projects.

Comprehensive Testing and Reliability

Hydrostatic and pneumatic leakage tests, conducted according to international standards, validate each bellow's integrity. High corrosion resistance and temperature tolerance up to 600C-subject to material choice-assure lasting performance in exhaust, air handling, and ducting applications.

FAQ's of Double miter Rectangle Expansion Bellow:

Q: How is the Double Miter Rectangle Expansion Bellow installed in industrial ducting systems?

A: Installation is performed by connecting the bellow via flanged, butt weld, or customized end connections, allowing integration into ducting, air handling, or exhaust lines. The method depends on site requirements and the end connection chosen by the client.Q: What movement capabilities does this expansion bellow offer?

A: It is designed for axial, lateral, and angular movements. This functionality accommodates thermal expansion, mechanical vibration, and misalignment in piping systems to help prevent damage and maintain operational efficiency.Q: When should I choose a multi-ply bellow over a single ply?

A: Multi-ply bellows are recommended when increased flexibility, pressure containment, or movement absorption is required in your application. Selection is guided by design parameters and performance needs specified by site conditions and client standards.Q: Where can this expansion bellow be utilized?

A: Ideal for use in industrial ducting, air handling equipment, exhaust systems, and other demanding environments where controlled thermal expansion and vibration absorption are critical. It's well suited for installations in India and global projects across the industrial spectrum.Q: What is the process for customizing the bellow to my project requirements?

A: Customization starts with a review of your site specifications, including required movement, dimensions, material, end connections, and applicable standards. Designs are tailored per ASME, EJMA, or IS codes, then manufactured and tested to meet performance and reliability goals.Q: How does the product ensure leakage prevention?

A: Each bellow undergoes rigorous hydrostatic and pneumatic leakage tests as per international standards. These measures confirm the unit's integrity and suitability for handling air, gases, steam, or other non-corrosive fluids securely.Q: What are the benefits of choosing this expansion bellow for high-temperature and corrosive applications?

A: Its selection of corrosion-resistant materials and ability to withstand temperatures up to 600C make it reliable for demanding environments. The customizable design ensures compatibility and performance in challenging settings where safety and durability are paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expansion Bellows Category

Fabricated Expansion Bellows

Price 35000.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Carbon Steel

Surface Treatment : Other

Max. Temperature : 400 Celsius (oC)

Working Pressure : 1000 Pa

Metallic Expansion Joints

Price 20000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Painted

Max. Temperature : 500 Celsius (oC)

Working Pressure : 1 kgf/cm2

Square Expansion Bellow

Price 5000.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Iron

Surface Treatment : Powder Coated

Max. Temperature : 20 Degree C to +200 Degree C Celsius (oC)

Working Pressure : 0.1 MPA2.5MPA mpa

Capsule Expansion Bellow

Price 7000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Powder Coated

Max. Temperature : 20 Degree C to +200 Degree C Celsius (oC)

Working Pressure : 0.1 MPA2.5MPA mpa

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese